更多 Planetary Mills

更多产品组别

产品详情

Technical data

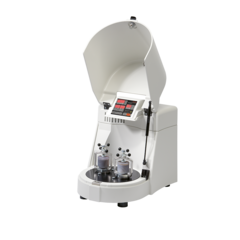

| Working principle | impact force |

| Optimal for material type | hard, medium-hard, soft, brittle, tough, moist |

| Number of grinding stations | 2 |

| Grinding tools | grinding bowls and grinding balls |

| Materials of the grinding tools | agate, zirconium oxide, hardened stainless steel, hardmetal tungsten carbide, silicon nitride |

| Grinding bowl sizes | 125, 150, 250, 420, 500 ml |

| Grinding ball diameter | 0.1 - 20 mm |

| Max. feed size (depends on material) | 10 mm |

| Sample quantity | 15-450 ml |

| Final fineness (depends on material) | < 0.1 µm |

| Typical grinding time down to analytical fineness | 3 min |

| Grinding process | wet and dry |

| Grinding in inert gas | yes |

| Gas pressure and temperature measurement | yes |

| Max. rotational speed grinding bowls | 1600 rpm |

| Rotational speed of main disk | 100-800 rpm |

| Transmission ratio planetary disk / grinding bowl | i relative = 1 : -2 |

| Effective diameter of main disk | 180 mm |

| Centrifugal acceleration (g = 9.81 m/s²) | 64 g |

| Interfaces | yes |

| Electrical Details, additional voltages available upon request | 200-240 V/1~, 50-60 Hz, 2800 watt |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground, grinding bowls/balls, selected rotational speed) | approx. LpAd = 84 dB |

| Weight | 110 kg |

| Dimensions (W x D x H) | bench top instrument 82 x 52 x 48 cm |