返回概览

Polymers & Plastic

Complex polymers. Reliable samples. Uncompromising quality.

Not all polymers are the same. Amorphous, semi-crystalline, filled, fibre-reinforced or additive-enhanced – each material reacts differently to energy input. Fritsch provides the instruments and expertise to turn this variety into reliable samples. Our instruments grind the sample in a controlled manner from coarse to fine, keep the temperature under control and prevent smearing, agglomeration and charging. The result is cool, homogeneous samples that are reliable for analysis and quality assurance.

Pre-grinding - the important first step

The P-19 is the first step. Two drive ranges – 50 to 700 revolutions per minute for high-torque, material-friendly processes and 300 to 3000 revolutions per minute for high throughput – cover a wide range of applications, from tough injection moulding residues to fibrous compounds. In combination with the FRITSCH cyclone, the ground material is continuously extracted from the grinding chamber: heat stays low, the sample remains free-flowing and homogeneity increases. Typical hurdles such as elastic rebound of amorphous thermoplastics near the glass transition temperature or inhomogeneous additive distribution can thus be planned for.

Perfect fine comminution

When particle size matters, the P-14 takes over. It is multifunctional, with a choice of impact rotor up to 24,000 revolutions per minute or cutting rotor up to 18,000 revolutions per minute – corresponding to impact speeds of 121.9 metres per second and 79.2 metres per second respectively – ensuring fast sample throughput. Feed sizes smaller than 15 millimetres, typical throughputs of up to 15 litres per hour and more, and final finenesses smaller than 40 micrometres with sieve rings from 0.08 to 6 millimetres are permitted.

Samples that are difficult to grind or sensitive to temperature can be embrittled with liquid nitrogen and then safely ground.

Process reliability is part of the design: intelligence safety control, temperature sensor and very high air flow keep the sample cool. Patented cooling of the grinding parts, targeted air flow and cooling fins on the rotors prevent melting and sticking. The grinding chamber and electronics compartment are completely separate – the electronics remain dust-free, the process air cooler and faulty switching is avoided. The cooling effect can be further increased with a cyclone; the P-14 can be operated either in batches or continuously.

Cleaning also follows this principle of clarity.

The clean design offers components that can be removed without tools (funnel, collection vessel, rotor, sieve ring/bowl holder, labyrinth disc). Laser-welded sieve rings reduce dead space and increase stability. A wear-free labyrinth seal separates the grinding chamber and the drive. The machine operates pleasantly quietly in accordance with European standards, can be remotely controlled, has an interface for data exchange and integrated control of the LABORETTE 24 vibration feed chute.

For sensitive applications, contact materials such as stainless steel 303 or 316L or polytetrafluoroethylene coating as well as grinding parts made of stainless steel 431 or 316L, pure titanium, tungsten carbide or zirconium oxide are available. In short: high cutting and impact energy meets powerful cooling and clean discharge. This allows you to achieve the target grain size quickly and reproducibly – without lubricating films and with low agglomeration. And because halving the particle size roughly doubles the specific surface area, the sample provides more signal for analysis; our instruments and application knowledge ensure process control.

Measurement delivers clarity

The ANALYSETTE 22 NeXT Nano uses laser diffraction to measure particle size distribution from 0.01 to 3800 micrometres. Most measurements take less than a minute, and cleaning is quick and residue-free. Evaluation and reports are generated automatically and can be adapted to your standard operating procedures. The method complies with the international standard 13320 for particle size analysis using laser diffraction and delivers repeatable, reproducible results. Reactive or moisture-sensitive powders are dispersed dry: a venturi nozzle breaks up agglomerates as they pass through, parts that come into contact with the sample are quickly dismantled, and the measuring cell can be opened without tools – keeping the routine efficient.

Size and shape matter

When shape is as important as size, the ANALYSETTE 28 ImageSizer supplements size analysis with morphology in less than five minutes. Telecentric optics, high-performance software and transparent display in FRITSCH Cloud and FRITSCH Gallery provide key parameters such as roundness, aspect ratio and convexity. The method complies with the international standard 13322-2 for dynamic image analysis and makes shape deviations visible at an early stage.

Turning routine into quality.

FRITSCH provides instruments and knowledge for the entire chain: P-19 for pre-grinding, P-14 for fine grinding and ANALYSETTE 22/28 for fast, reliable particle size and shape analysis. Heat build-up, melt smearing, agglomeration, charging, wear and contamination are solved where they occur – with speed strategy, cooling, cyclone discharge and easy-to-clean design. This turns complex polymers into a reliable sample. And routine into quality.

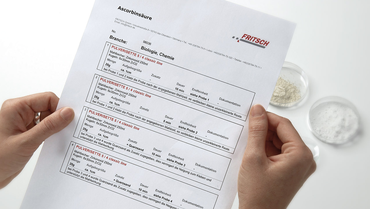

Fritsch Lab Know-How

Our applications laboratory is the heart of FRITSCH. We examine the tasks that you deal with every day. We work through different configurations of the instruments until the best results can be shared with you. Tell us your objective. We will bring our instrument to your laboratory, determine the optimum grinding parameters and impress you with outstanding results. You can also visit one of our regional experts at their facility. Either way, it results in a detailed grinding protocol.

Just contact our lab!

返回概览