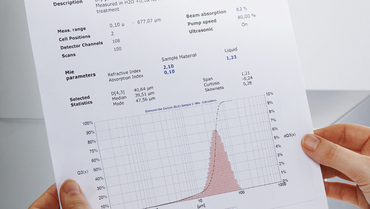

Clean measuring cell – precise results:

How to identify and resolve contamination in the ANALYSETTE 22 NeXT

When using the A-22 NeXT, one thing matters most: maximum precision. But even the best particle size analyser can only deliver accurate results if the measuring cell is free of residues. Contaminants – whether from sample deposits or build-up – can affect light scattering and distort your results.

How can you tell the measuring cell is contaminated?

• Implausible measurement results or inconsistent repetitions

• Visible residues or cloudiness on the measuring cell windows

• Deviations during the weekly test using the FRITSCH Test Standard (F500/F70)

Why is cleaning so important?

The measuring cell windows are made of ultra-hard sapphire glass, which is highly scratch-resistant. However, they feature a delicate anti-reflective coating on the outside that is sensitive. Even the slightest scratch in this coating can impact light scattering and compromise your measurement results. That’s why it’s essential to clean using optical-grade lens tissue and minimal pressure – never with abrasive cloths. We strongly recommend regular inspection and, if needed, careful cleaning with the appropriate materials as described in the manual.

Practical tip:

The A-22’s measuring cell can be removed, cleaned and reinserted in just a few simple steps. The eccentric locking mechanism, convenient sealing rings and our tutorial videos make the process easy. Cleaning the glass surfaces with optical tissue and a light spray of alcohol is also demonstrated in detail.

Conclusion:

Regular cleaning isn’t just routine maintenance – it’s a vital part of your quality assurance. To get the best performance from your ANALYSETTE 22, don’t lose sight of the measuring cell.