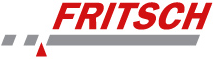

Welcoming our U.S. Exchange Student

We welcome our U.S. Exchange Student: He's advancing his studies with lab mills and particle Sizing technology here in our application lab. Meet William and read what it's like to being part of the FRITSCH Team:

What inspired you to come to Germany and work in our lab?

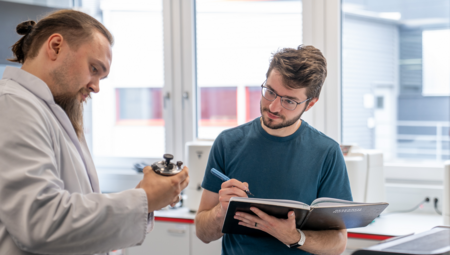

I was inspired to come work with the team in Germany due to my research on particle size effects at Virginia Tech with Dr. Christina Rost. I helped organize a trip for 17 of our materials science undergraduate students to attend the 2024 MS&T conference and participate in the student design competitions. After winning the ceramic disk golf competition we were set loose on the Advanced Materials Show. I made a list of every company at the expo who made equipment for milling or particle sizing and tried to talk to as many as I could. That's how I met Maik Paluga and we connected through our love of science. I talked to him as well as Melissa and Jeff for probably 30+ minutes. The Fritsch team had the kindest staff members and the best equipment, so I sent the team an email and everything snowballed from there! I’ve been looking forward to learning as much as I can from my time in Germany.

How does this experience connect to your studies or career goals?

I’m researching high entropy oxides which are a relatively new type of ceramic material that have exciting and novel properties. My specific branch of research is understanding how particle size may affect the phase stability of these high entropy oxides. This research involves milling ceramic powder and measuring the resulting particle size and properties which fits perfectly into Fritsch’s product portfolio and expertise. I was able to present my research at the 2025 Electronic Materials and Applications conference, but this is an ongoing project which has reached some limitations with my current equipment. I hope by partnering with Fritsch I’ll be able to take my research to the next step.

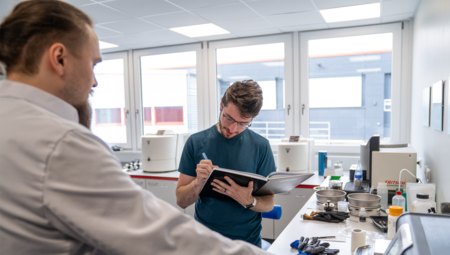

What kind of projects or tasks will you be involved in during your time here?

While at Fritsch I hope to obtain a better understanding of milling parameters, and how they affect the final sample. Specifically I would like to practice how to repeatably mill a powder into nano particles then verify their particle size. While working in Germany I will also be helping test prototype equipment with Leos.

Have you worked with similar equipment before, or was this your first time?

I've worked with a variety of milling and particle sizing equipment during my time at Virginia Tech including roller mills, cryomills, sieve analysis, and laser diffraction, so I feel well equipped to jump headfirst into everything at Fritsch.

What was the most surprising thing you learned about our technology or processes?

The previous mills I've worked with are much lower energy than the Pulverisette 7 Premium and I was shocked to see how quickly you can mill powders using this system. It's a fantastic example of German engineering quality.

How do you think this experience will influence your academic or professional journey going forward?

I'm incredibly grateful for the opportunity to work with a company that is so closely aligned with my current research trajectory. The experience of working with one of the best milling and sizing companies in the world is a fantastic way to help accelerate my research and give me industry experience and exposure to new techniques and processes that I can use in my future academic life.