MENU - PARTNER AREA

Virtual Product Presentation

With the virtual product presentation you can experience our particle sizers for automatic particle size and shape analysis directly at your workplace.

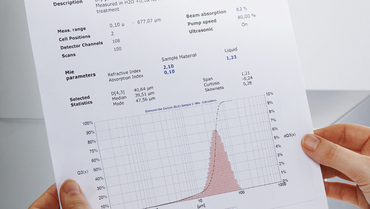

粒子分析仪 ANALYSETTE 22 NeXT – 粒子分析仪 非常简单的粒度自动分析

我们的两种型号的ANALYSETTE 22 NeXT是生产和质量控制、研发或生产过程控制中高效粒度分析的理想选择。

两种粒度仪的设计和测量范围不同。

ANALYSETTE 22 NeXT Micro缩减为一个光源和一个探测器,测量范围从0.5到1500μm,坚固可靠。

ANALYSETTE 22 NeXT Nano通过增加额外的探测器系统的智能布置,能够测量更小的粒子。这使得设备可以记录更大的散射角和低至0.01 μm的侧向和后向散射角。同时,测量上限也被提高到了3800 μm。

该仪器具有可满足您的要求的所有决定性的优势:特别是操作和清洗方便,分析时间短,结果可重复性好,并可记录湿法分散过程中的温度和pH值等附加参数。

ANALYSETTE 22 NeXT是根據智慧模組化概念開發的。你只買你現在真正需要的東西。我們可以靈活地完成您的測量任務。這些模組可以隨時添加,並且我們正在不斷開發產品群組。最先進的技術,無與倫比的價格。做得很巧妙!

根据您的要求选择

2 结果

Details

ANALYSETTE 22

NeXT Micro

- Method of analysis

- Static Light Scattering

- Measuring range

- 0.5 - 1500 µm

- Sample carrier medium

- almost all dispersion liquids

- Suspension/sample volume

- 150 - 500 ml, variable

Details

ANALYSETTE 22

NeXT Nano

- Method of analysis

- Static Light Scattering

- Measuring range

- 0.01 - 3800 µm

- Sample carrier medium

- almost all dispersion liquids

- Suspension/sample volume

- 150 - 500 ml, variable

下载

Product Profile Laser Particle Sizers ANALYSETTE 22 NeXT

型激光粒度仪ANALYSETTE 22 NeXT产品宣传册

Webinar Measurement of particle size distribution using laser diffraction

播放视频